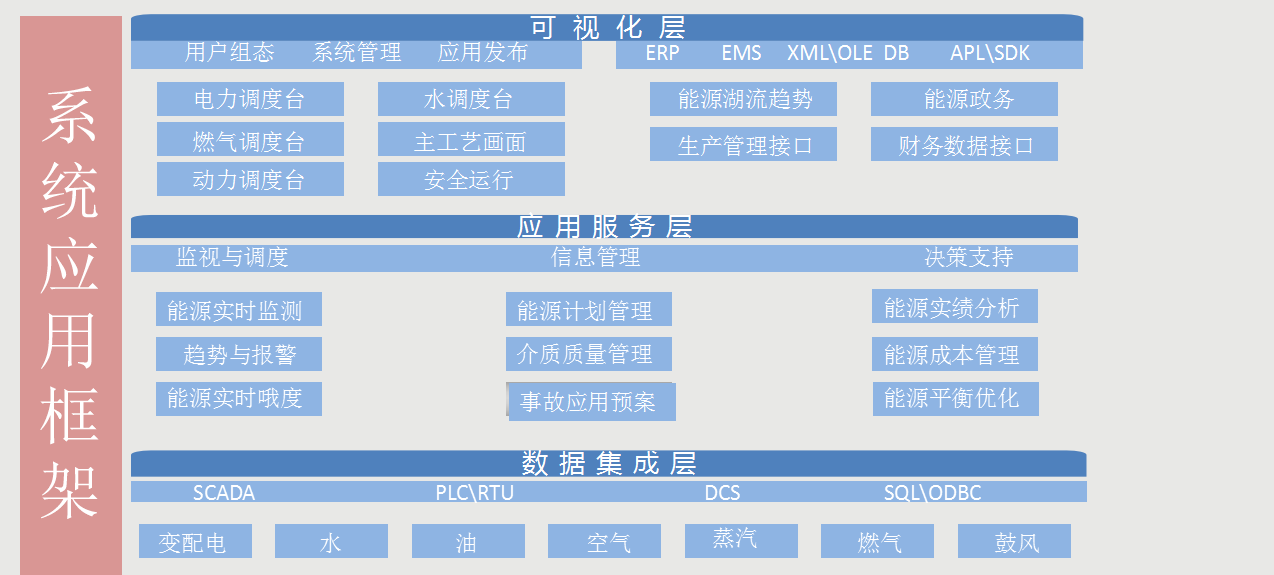

Model: Enterprise energy management system

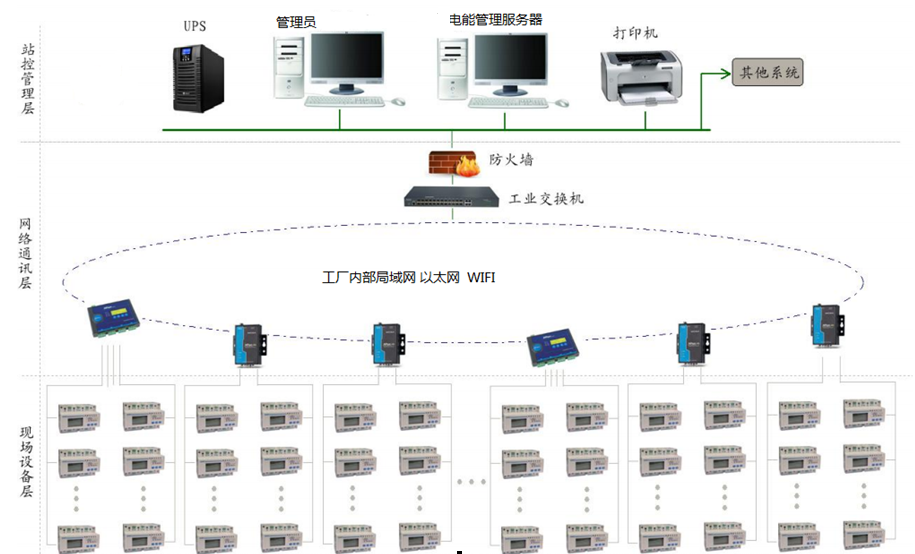

According to the realization of the function can be divided into two parts: on-site industrial data collection and data network transmission.

The main function of on-site industrial data collection is to convert electrical data (phase-phase current, voltage, power factor, active power, reactive power, etc.) and steam, water flow, and pressure signals into 485 communication signals. Its specific form consists of:

Current transformers and voltage transformers installed in the circuit of electrical equipment (380V direct lead-out without voltage transformer) and cables

Smart Meter

485 communication cable

1, automatic monitoring system composition

According to the realization of the function can be divided into two parts: on-site industrial data collection and data network transmission.

The main function of on-site industrial data collection is to convert electrical data (phase-phase current, voltage, power factor, active power, reactive power, etc.) and steam, water flow, and pressure signals into 485 communication signals. Its specific form consists of:

1) Current transformers and voltage transformers installed in the circuit of electrical equipment (380V direct lead-out without voltage transformer) and cables

2) Smart Meter

3) 485 communication cable

The main function of data network transmission is to convert 485 communication signals into TCP/IP network signals. Its specific form:

1) serial port server

2) Optical fiber or network cable.

2, network communication system

The system will automatically collect the network signals collected by the system and send them to the server and realize

With the monitoring host, host computer, Internet cloud, mobile phone terminals and other similar network communication functions, and can carry out GPS clock calibration. Its specific form consists of:

1) Terminal communication equipment such as switches, optical fiber terminals, and network cabinets

2) Server, UPS power supply

3) The host has a monitor

4) User peripherals such as upper computer and printer.

3, application software and management system.

The Hiroshima Energy Management System is the configuration platform software. Different from general application software and configuration software, the Hiroaki configuration platform software has a large number of application libraries, which can be added and deleted according to the site, can be used for secondary development, information can be shared, and software modules in the application warehouse can be used during implementation. Configure and use the interface in accordance with the application software. Any application under this platform is open and shared, can be secondary development, and can generate specific application software to meet business needs according to the needs of users. These specific applications can also be from the application warehouse in addition to specific development. Get it directly. Applications that have been generated include energy management systems, plant energy management systems, building automation and energy management systems, intelligent power distribution systems, online temperature monitoring systems, photovoltaic power station monitoring systems, and more. Application warehouse also provides more convenient and quick service modules.

The configuration platform software can control data, images, and sounds together in a centralized platform. The service program supports both client and server modes. According to specific needs, it can be configured as C/S mode or B/S mode. At the same time also supports R485, network and other technologies.

The Hiroshima Energy Management System is compatible with the Windows series platform, has a good human-computer interaction interface, the client has a dedicated Andriod version, supports PDA or tablet PC. It is easy to use, convenient, flexible, stable, reliable, easy to maintain, and has good expansion performance.

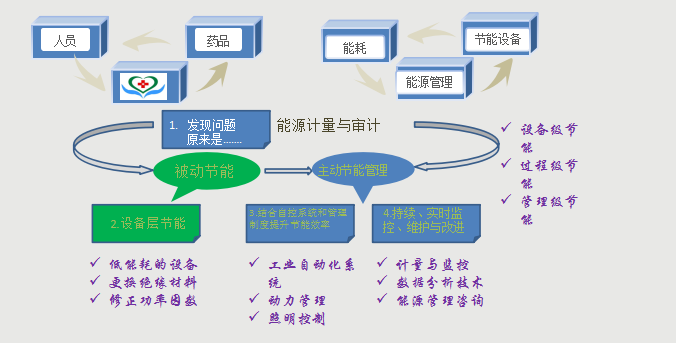

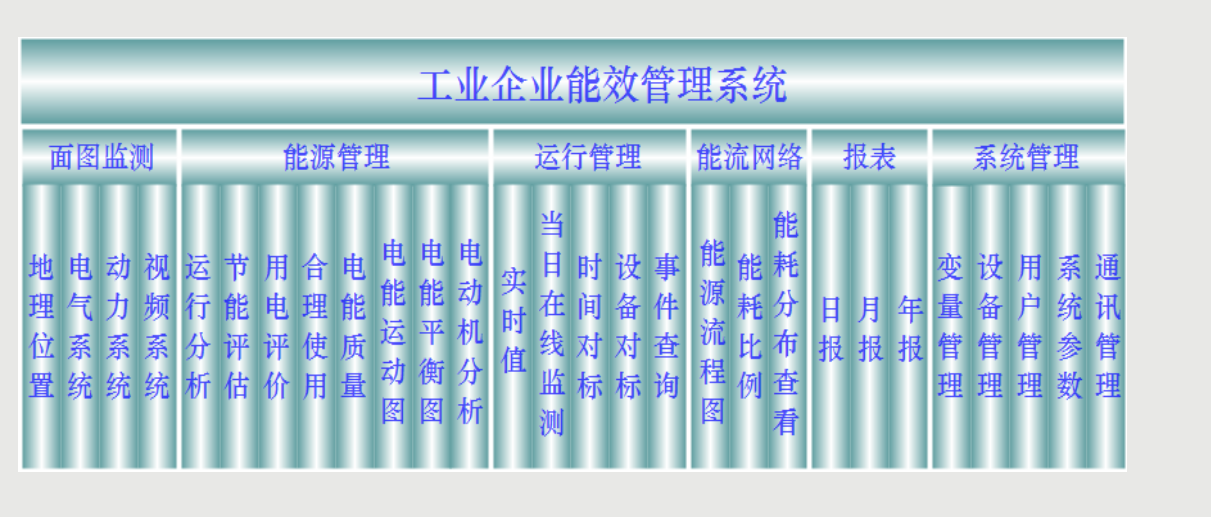

Energy Management System Features

Plan

Introduce the factory map information, directly associate with the equipment status, and quickly locate the geographical and operating status of the equipment

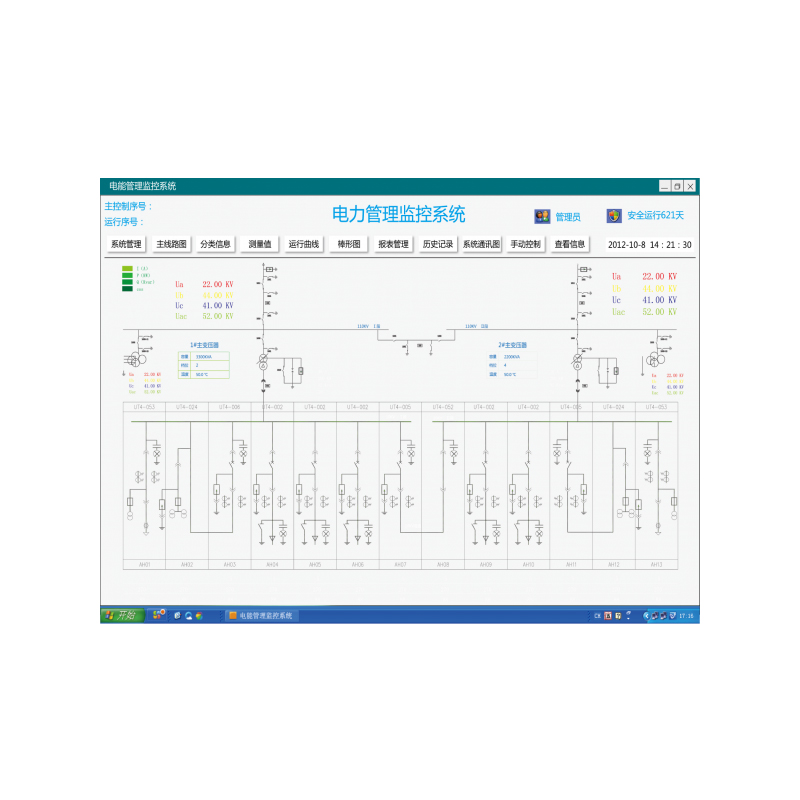

Distribution network monitoring

Distribution network monitoring Through monitoring the real-time data of the equipment, the overall understanding of equipment operating conditions, intuitive and clear display of power parameters under each monitoring point. The overall graphic layout can reflect the distribution and correlation of the entire power facility.

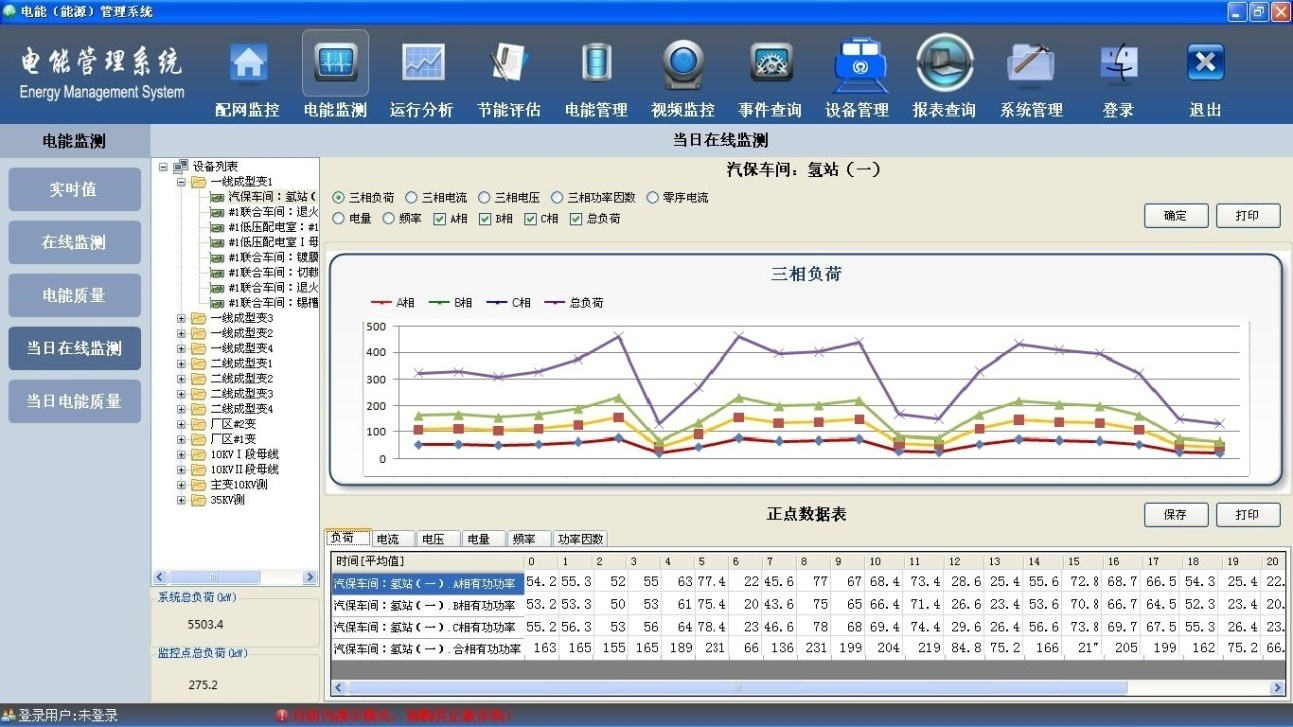

Power monitoring

Provides power management personnel with real-time operational data for monitoring the power and power quality of the enterprise distribution network, as well as the power and power quality operating data of the day, and guides the power management personnel to analyze power, electricity, and power quality data of the distribution network.

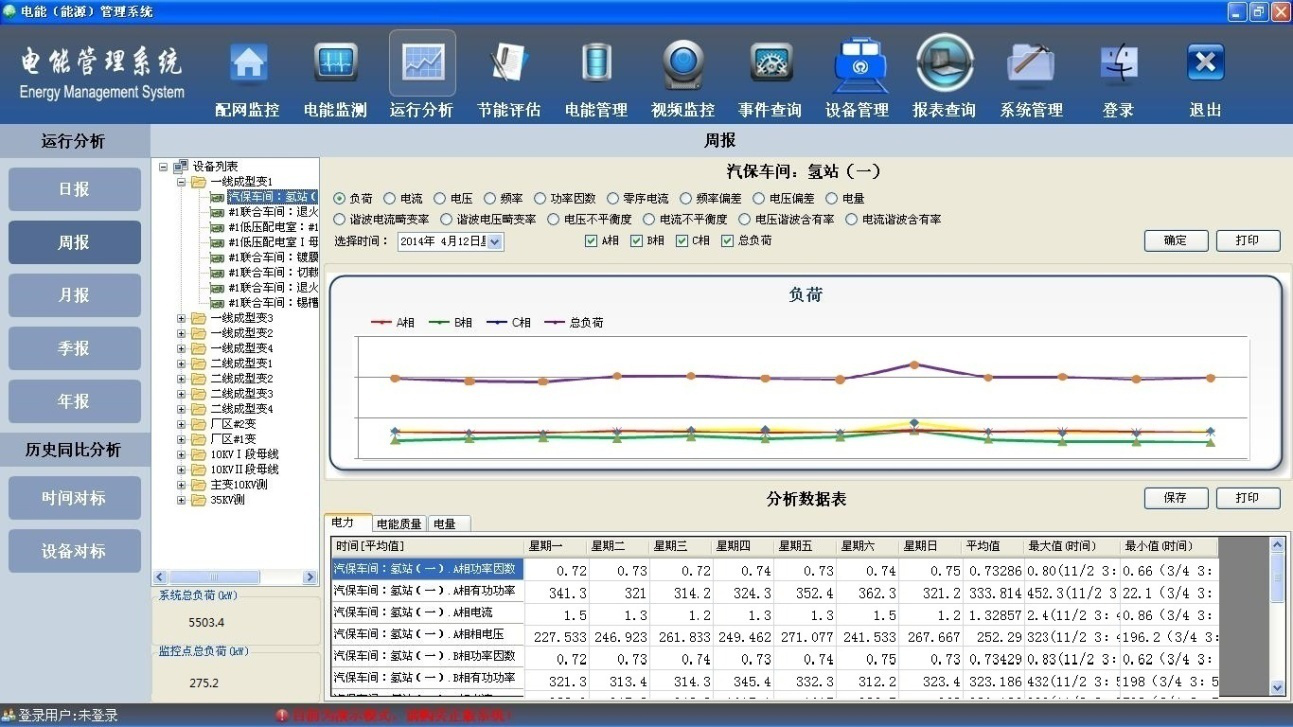

Operational analysis

Provides power management personnel with daily, weekly, monthly, quarterly, and annual energy analysis reports. The report displays power energy indicators in the form of curves and tables, and compares data from electricity, power quality, and power, and guides power. Managers analyze the operation of the distribution network.

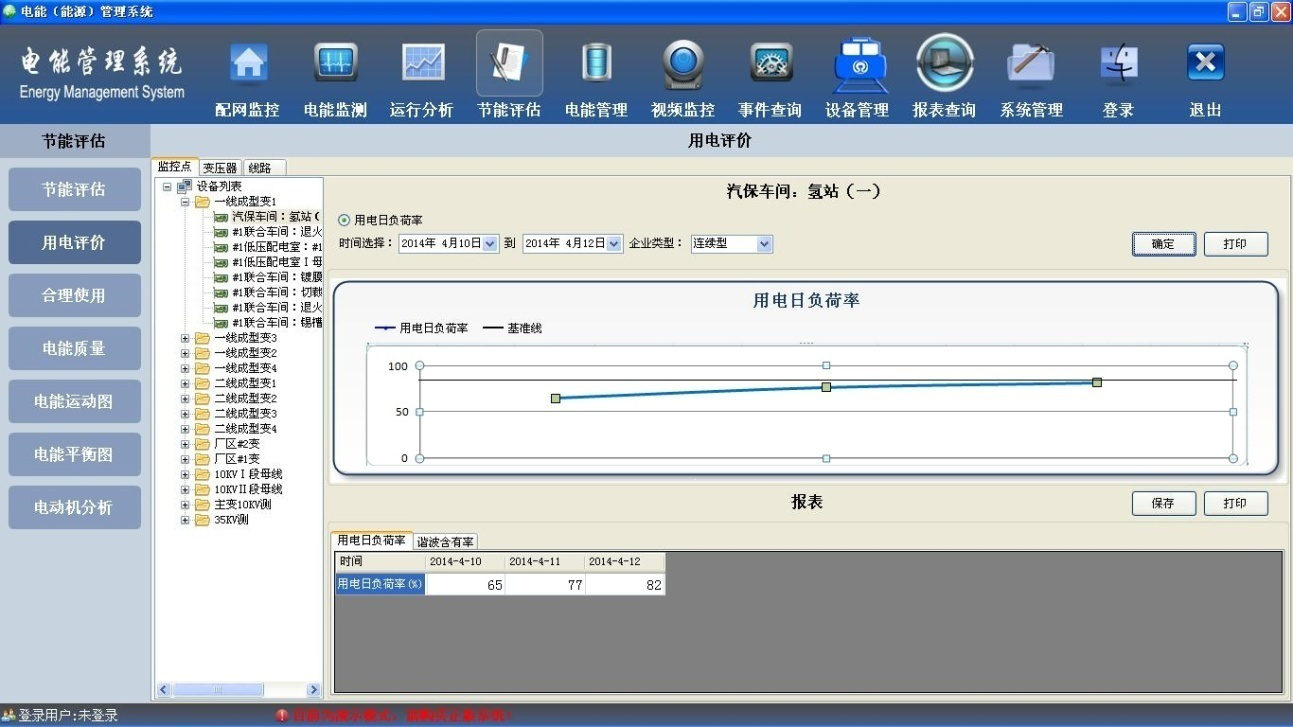

Energy-saving assessment

Evaluation of enterprise power consumption and space-saving evaluation of electricity is an important part of the enterprise's power management. It mainly allows the enterprise's power management personnel to know the power consumption level of the enterprise and the power-saving space that exists.

Power Management

The assessment of electricity consumption at monitoring points. The assessment cycle is divided into five parts: day, week, month, quarter and year. From this functional module, we can see the power consumption of products and people at the monitoring point.

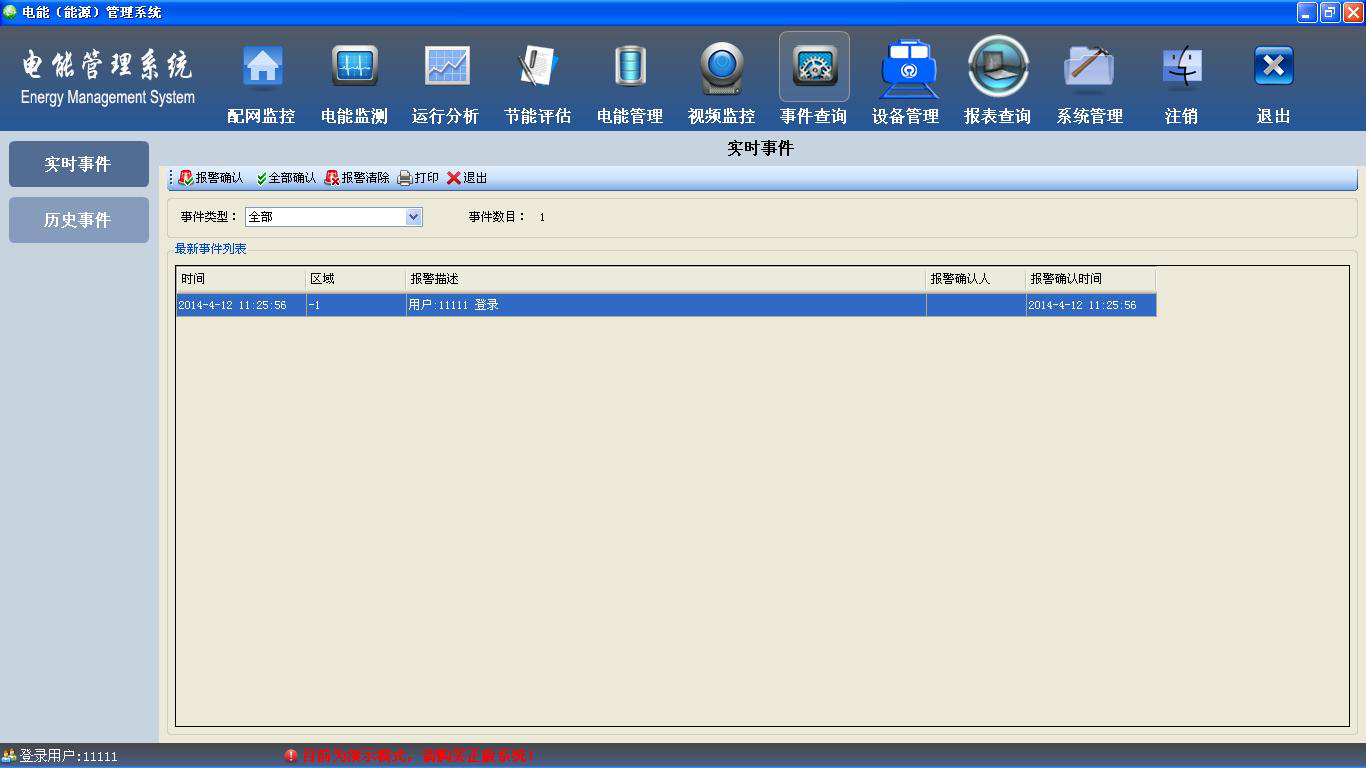

Event query

Divides real-time events and historical events, and queries system, operator, accident information, and user-requested events (event types can be customized).

Equipment Management

The electrical energy of an enterprise depends on the distribution network and electrical equipment. It is necessary to scientifically and effectively manage the electrical energy. It is necessary to manage distribution network facilities and electrical facilities. The management of these devices must first establish its own files so that all power management information can have its own roots. The monitoring points, monitoring point equipment, distribution lines, distribution cabinets, distribution equipment, transformers and motors can be managed and configured.

Report Query

The report is a kind of report on the important information in the monitoring system. It is an important form of formatting the information layout to reflect the data and status in the production process and record the data. It is an integral part of the production process. Through the report can quickly collect and display the specified production process data, the report can not only reflect the real-time production of the system, but also the long-term production process statistics, analysis, so that managers can grasp and analyze production conditions in real time. The software provides a powerful reporting system that can easily read historical data, perform various calculations and statistical analysis. The typesetting method is also very flexible and can discharge multiple layout formats.

Reports are divided into Excel reports and web reports. Excel reports support local data and remote data queries. In addition to supporting local and remote data queries, web reports also support web page queries.